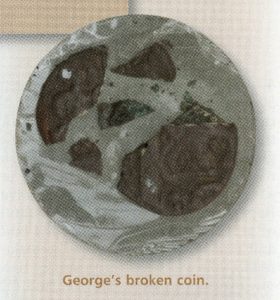

George handed me a 2 x 2 inch cardboard coin holder and, with tears in his eyes, said: “Can you mend this for me?” I looked, in horror, at what appeared to be the shattered remains of a coin as George explained that it was once an Iron Age silver unit that he had been carrying around in his pocket to proudly show his friends.

Cardboard coin holders fold over the coin and retain it in a circular Mylar plastic window, created by sticking or stapling the two card halves together, they are then usually stored in an appropriately sized coin filing or storage box. The holders are perfectly adequate for protecting robust modern coins under most circumstances, but they are too flimsy to protect fragile and brittle older coins other than in a rigid container with suitable packing to stop the coin holder moving around. Personally, I prefer the rigid plastic coin capsules for transporting old coins; even then, unless the coin fits snugly, I like to pack the coin within the capsule with jiffy foam or acid-free tissue.

If you need to join parts of coins or artefacts together in the way of a repair, ideally the join should be reversible so that it can be dismantled if there is an error or for some other reason. Similarly coatings (lacquer) may need to be removed to deal with internal corrosion. Paraloid B72 is a glass-clear, non-yellowing soluble plastic, highly recommended by conservationists for joining and lacquering metals. Joins can be easily taken apart and coatings removed by brushing Acetone over the object with a fine brush. Made-up adhesive and lacquer are available from conservation material suppliers. However, the product contains a flammable solvent, which Royal Mail and most other postal services won’t carry, so transport costs are very high. Nevertheless I have devised a cunning plan to get around this. Paraloid B72 itself is available as solid plastic beads, which can be sent by post and the solvent, Acetone, can be sourced locally, so you can easily and quickly make your own adhesive and lacquer.

I am offering small bags of Paraloid B72 beads for dissolving in 50ml Acetone on Ebay as follows:

5gm makes 10% lacquer

10gm makes 20% lacquer

25gm makes 50% adhesive

25gm + 5gm makes 50ml each lacquer and adhesive.

I recommend buying the Care+ brand 50ml Acetone bottles available at many local chemists and online from suppliers with transport arrangements.

If you buy Acetone in a small bottle like this you can safely make-up and store your adhesive or lacquer in the same bottle. If you buy larger quantities of pure Acetone – you don’t want it coloured or perfumed as is often the case with nail polish remover -then it will be best to find small sealable glass bottles to use for adhesive and lacquer as Acetone will dissolve its way through some plastic bottles (HDPE, High Density Polyethylene is Acetone resistant). Acetone is used in glass reinforced plastic (fibreglass) construction and repair, so you will also find it at auto parts shops and yacht chandlers in larger quantities.

To make our adhesive we need to dissolve 25gm Paraloid B72 beads in 50ml Acetone to make a 50% solution; and dissolve 5-10gm Paraloid B72 beads in 50ml Acetone to make a 10-20% solution of lacquer (I prefer 10%). Using the 50ml or similar bottles of Acetone, you can just pop a few beads at a time into the appropriate bottle, wearing surgical gloves or using tweezers (as the plastic beads may irritate the skin), until the liquid reaches the top, screw the top on and shake or leave to stand until dissolved. Repeat until the appropriate quantity of beads are in solution, label the bottle and that is all there is to it. To make a repair, ideally, you will need three bottles, one each of adhesive, lacquer and pure Acetone.

The first thing I needed to do with George’s coin was to lay the pieces out on a solid surface and fit it all together dry, with the design and breaks all matching up. I needed to work under a hands-free magnifier for this tiny coin and also had to use tweezers to handle the very small pieces. When I had the pieces together, I noticed there was a piece missing out of the edge. I discussed this with George, who said that the coin was like that when he found it and yes, he would like me to fill in the gap.

I use a machine vice to hold small objects steady while I work on them. The jaws of these vices are too deep to just put in slim objects like coins, so I use thin pieces of wood or Lego bricks, narrower than the object I am holding, to make a platform near the top of the jaws. When I am using adhesive or lacquer I put Silicone release paper (the backing paper for self-adhesive labels and the like) on the top surface of the platform, held in place by a couple of pieces of sticky tape, so that, at worst, the object being glued only sticks to the paper, which can be peeled off easily.

Starting with the largest coin fragment, I put this in the vice, making sure the edge to be joined was accessible and unobstructed. The vice has to be tightened very gently, and I mean “touch of a butterfly’s wing” gently, otherwise the object you are trying to hold steady could bend, buckle or shatter. Once the main fragment was held, I placed the next fragment to be joined on alongside, with a small gap in between the two pieces. I then applied the adhesive generously with a cocktail stick to the broken edge of the main fragment, and pushed the smaller fragment firmly into place with tweezers and held it there for about a minute. The adhesive oozes out of the join but that isn’t a problem as it will be dealt with later. After about 15 minutes the adhesive had dried, so the coin could be carefully repositioned in the vice to expose the next edge to be joined and the gluing process repeated and so on, until all the fragments were reunited.

George’s coin had a roughly triangular piece missing, which needed filling to make the repair stronger and at the same time improve the coin’s appearance. Bearing in mind that repairs may need to be undone and fillers are not easy to remove, before any filling takes place a liberal coating of Paraloid B72 lacquer should be applied to the edges of the section and immediate surrounds so that the filler sticks to the lacquer and not to the coin itself. If it is necessary to undo the repair, the lacquer can be dissolved with Acetone and the filler will fall out.

A suitable filler is a two-part polyester resin, such as Plastic Padding or David’s Isopon, originally formulated for car and boat body repairs but now used around the home too and readily available from hardware stores as well as auto parts shops and yacht chandlers. The package contains two tubes, one of resin and the other of catalyst or hardener. To use the filler you squeeze out equal lengths of “paste” from the two tubes onto a scrap piece of say, plastic or cardboard; mix the two together thoroughly and use within five minutes before the mixture sets rock-hard.

I placed the coin on a piece of Silicone release paper and had a cocktail stick and scalpel to hand. Using the cocktail stick I mixed the hardener with the resin and transferred the mixture into the gap, roughly shaping the filler to the profile of the coin. Just as the filler was going hard, I trimmed the uneven edge with the scalpel then left it to harden. It is important to get the repair as good as possible before the filler hardens as in this application; realistically, you are not going to be able to make any changes! To hard filler and you would have to dissolve out failures and start again. I could have attempted to carve missing features into the filler but since we can only guess what might have been there, I just left the filler with a rough surface to blend in. To finish off, I gave the hard filler a coating of silver Humbrol model paint. The final job was to coat the complete coin in Paraloid B72 lacquer, which fills any small cavities and effectively encapsulates the entire coin in a plastic film, holding it more firmly together. As the lacquer can soften the adhesive to the extent that the joins come apart, lacquering is best carried out back in the vice. With so many joins in George’s coin I couldn’t clamp across all of them so with the reverse side up, where the join lines were more prominent, I positioned the coin so that I could hold two main joins together and just watched that nothing came adrift elsewhere. Using a clean small artist’s paint brush I coated the reverse of the coin with lacquer then looked for any solid lumps formed or left behind from the gluing process. As there were a few lumps, I brushed them out with acetone and they disappeared into the lacquer coating. Once the lacquer was dry, I turned the coin over in the vice and lacquered the obverse in the same manner. When that was dry I took the coin out of the vice, held it between finger and thumb, lacquered the edge and allowed it to dry. The repaired coin was now easy to identify in Ancient British Coins, as an Iceni, Bury diadem silver unit, which, because of its protective coat, could now be handled with reasonable care and displayed with impunity.

At the next club meeting, I handed the coin, in a coin capsule, back to George without comment to which George said: “That’s nice, where did you find it?” I quipped something about finding it locally and left George to look at his coin. Ten minutes later George came back to me and said: “That’s my coin isn’t it? It looks better than when I found it.”

Recent Comments